Application of optical precision prism-cubic reference prism in spacecraft development process

Application of Cube Reference Prisms in Spacecraft Development Process Cube Reference Prisms are a type of precision optical element. Its unique structural design and manufacturing accuracy make it play a vital role in the development process of spacecraft. effect. This regular hexahedron not only has extremely high geometric stability, but the angular error between its adjacent faces is usually controlled within a very small range, only 2 to 5 seconds. More importantly, 3-5 adjacent surfaces of the cubic reference prism are coated with reflective films and cross lines. These characteristics make it an indispensable part in the development of spacecraft.

During the manufacturing and testing of spacecraft, precise measurement and positioning are key. Every component of the spacecraft needs to be placed precisely in three-dimensional space to ensure the performance and stability of the entire system. The cubic reference prism is an important tool to achieve this goal. By measuring the normal of the cubic reference prism reflection surface with an electronic theodolite, an accurate cubic mirror coordinate system can be constructed. This coordinate system can not only represent the spatial position of the product, but also provide an accurate benchmark for subsequent assembly and testing.

In the development process of spacecraft, the application of cubic reference prisms is not limited to constructing coordinate systems. Due to its high stability and precise reflection properties, it can also be used in spacecraft attitude measurement and control systems. By monitoring the beam reflected by the cubic reference prism, the attitude and position of the spacecraft can be accurately determined, thereby providing key information for the navigation and control of the spacecraft.

In addition, cubic reference prisms are also widely used in spacecraft optical systems. Due to the presence of its reflective film and reticle, it can be used as a mirror or beam splitter in optical systems. This makes the cubic reference prism play a vital role in the optical system of the spacecraft, providing precise optical components for the spacecraft's imaging, detection and communication tasks.

However, the fabrication and application of cubic reference prisms also faces some challenges. First, due to its complex structure and high precision requirements, the manufacturing process requires an extremely high level of technology and strict quality control. In addition, due to the extremely harsh working environment of the spacecraft, the cubic reference prism needs to have extremely high stability and durability. This requires manufacturers to strictly control material selection, process design and quality control.

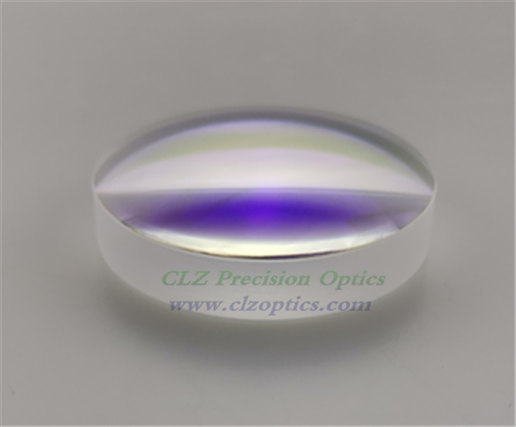

Achromatic Lenses (Achromatic Doublets)

ASTM F392 - Gelbo Flex Conditioning

4 Advice to Choose a Portable Leeb Hardness Tester

5 most common types of leak testing—and when to use them

How Custom Prisms Redefine Personalized Home Decor?

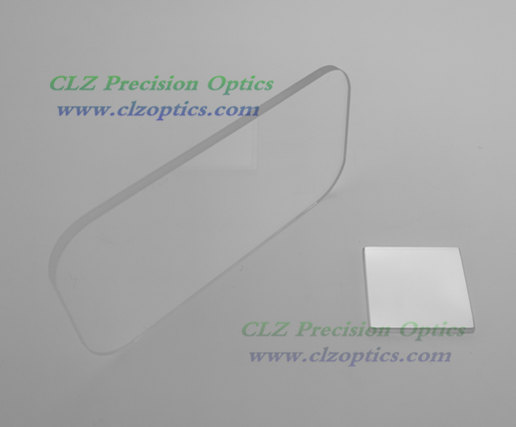

Optical Windows: the Ultimate Guide

The Relationship between the Hot Tack of Packaging ...

In general, cubic reference prisms play a vital role in the development of spacecraft. It not only provides an accurate reference and coordinate system for the manufacturing and testing of spacecraft, but also plays a key role in the attitude measurement, optical system and control system of the spacecraft. With the continuous development of aerospace technology, the application of cubic reference prisms will continue to be expanded and optimized to provide more accurate and reliable support for future aerospace exploration.

In the future, with the continuous advancement of aerospace technology and the increasing complexity of spacecraft, the accuracy and stability requirements for cubic reference prisms will also continue to increase. To meet these requirements, manufacturers need to continuously improve manufacturing processes and material selection to improve the performance and quality of cubic reference prisms. At the same time, researchers also need to continue to explore new application fields and technological innovations to further expand the application range and depth of cubic reference prisms in spacecraft development.

In addition, as spacecraft missions become increasingly complex and diverse, cubic reference prisms also need to adapt to more working environments and mission requirements. For example, in deep space exploration missions, spacecraft need to face more complex and harsh environmental conditions, which requires cubic reference prisms to have higher radiation resistance and temperature resistance. At the same time, in manned space missions, the comfort and safety requirements of spacecraft are also higher, which requires that the cubic reference prism needs to pay more attention to humanization and safety considerations in the design and manufacturing process.

In summary, as an important component in the development of spacecraft, cubic reference prism has broad application and development prospects. With the continuous advancement of technology and the increasing complexity of spacecraft missions, cubic reference prisms will play a more important role in future aerospace exploration. At the same time, manufacturers and researchers also need to continue to work hard and innovate to meet the higher requirements and expectations for cubic reference prisms in spacecraft development.

翻译结果

翻译Application of Cube Reference Prisms in Spacecraft Development Process Cube Reference Prisms are a type of precision optical element. Its unique structural design and manufacturing accuracy make it play a vital role in the development process of spacecraft. effect. This regular hexahedron not only has extremely high geometric stability, but the angular error between its adjacent faces is usually controlled within a very small range, only 2 to 5 seconds. More importantly, 3-5 adjacent surfaces of the cubic reference prism are coated with reflective films and cross lines. These characteristics make it an indispensable part in the development of spacecraft.

Power Quality Metering / Monitoring Solutions

Power Quality Metering / Monitoring Solutions

Understanding the Tack and Peel of Adhesive Tapes

How to Select the Best Magnesium Fluoride (MgF2) Crystal ODM?

How Magnesium Fluoride Crystals Enhance Technology Today?

How Does Smart Home Technology Integration Work?

2024 Trends in Optical Glass Window Export