Understanding the Strength of 301 Stainless Steel

Stainless steel is a popular choice for many applications due to its strength and corrosion resistance. 301 stainless steel is a particularly strong and versatile option that is commonly used in a wide range of industries. In this guide, we will explore the key factors that contribute to the strength of 301 stainless steel.

### Step 2: Chemical Composition.

One of the reasons why 301 stainless steel is so strong is its chemical composition. It contains high levels of chromium and nickel, which help to enhance its strength and corrosion resistance. Additionally, the presence of carbon in 301 stainless steel contributes to its high tensile strength.

### Step 3: Cold Working.

Another important factor that contributes to the strength of 301 stainless steel is the process of cold working. Cold working involves deforming the metal at room temperature, which helps to increase its strength and hardness. 301 stainless steel is particularly well-suited to cold working, making it an ideal choice for applications where high strength is required.

### Step 4: Heat Treatment.

Additional reading:Revolutionizing Home Plumbing: Are Welded Pipe Fittings the Future?

Why Cast Steel Swing Check Valves Are Essential?

What sets apart workover rig from drilling rig?

Everything You Need to Know About Bearing Preload Disc Springs

Revolutionizing Industry Standards: The Future of 3-Way Stainless Steel Ball Valves?

How Forklift Attachments Affect a Forklift Load

When to Use sanitary ball valve supplier?

Heat treatment is another process that can further enhance the strength of 301 stainless steel. By subjecting the metal to high temperatures and then rapidly cooling it, the structure of the steel can be altered to improve its mechanical properties. This can result in increased hardness and strength, making 301 stainless steel even more durable.

### Step 5: Applications.

Given its impressive strength and corrosion resistance, 301 stainless steel is used in a wide range of industries. It is commonly found in automotive components, kitchen appliances, and construction materials. Its high strength-to-weight ratio also makes it a popular choice for aerospace applications.

### Step 6: Conclusion.

In conclusion, the strength of 301 stainless steel can be attributed to its chemical composition, cold working, and heat treatment processes. These factors work together to create a metal that is not only strong and durable but also resistant to corrosion. By understanding the unique properties of 301 stainless steel, manufacturers can choose the right material for their specific applications and ensure the longevity and performance of their products.

Contact us to discuss your requirements of Belleville Spring Washers manufacturer, belleville washer supplier, 17 7ph stainless steel belleville disc washers. Our experienced sales team can help you identify the options that best suit your needs.

Additional reading:4 Advice to Choose a industrial check valve manufacturer

Belleville washers - Mechanical engineering general ...

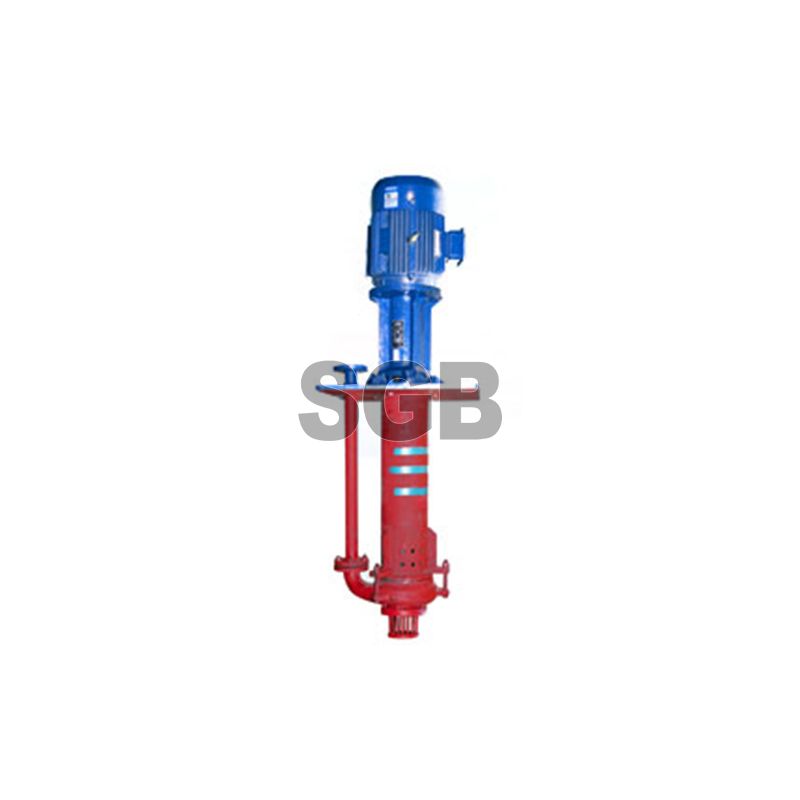

Centrifugal Pump: Understanding Its Mechanism and Functionality

Mechanical Seal vs. Oil Seal: Understanding the Differences and Applications

What Materials Are Used for Injection Molding?

Flux Cored Hardfacing Welding Wire: The Ultimate Guide

Why use a proportional valve?