Mechanical Seal vs. Oil Seal: Understanding the Differences and Applications

Introduction: Seals play a critical role in preventing fluid leakage and ensuring the efficient operation of various mechanical systems. Two commonly used seals are mechanical seals and oil seals. While both serve the purpose of sealing, they differ in terms of design, function, and application. In this article, we will explore the differences between mechanical seals and oil seals, helping you understand their distinct characteristics and their respective uses in different industries and applications.

Design and Function: Mechanical seals are complex sealing devices designed to prevent leakage of fluids, such as liquids or gases, in rotating equipment. They consist of multiple components, including stationary and rotating faces, springs, and secondary sealing elements. The primary function of a mechanical seal is to maintain a dynamic sealing interface between the rotating shaft and the housing, effectively sealing the fluid within the system.

Application: Mechanical seals are commonly used in pumps, mixers, compressors, and other rotating equipment where fluid containment is critical. They are suitable for applications involving high pressures, high speeds, and a wide range of fluid types, including corrosive or hazardous substances. Mechanical seals find extensive use in industries such as oil and gas, chemical processing, power generation, and wastewater treatment.

Performance and Advantages: Mechanical seals offer several advantages, including:

a. Effective Leakage Control: Mechanical seals provide excellent sealing performance, minimizing or eliminating fluid leakage from the equipment. They offer a higher level of containment compared to other sealing methods.

b. Versatility: Mechanical seals can be customized for specific applications, accommodating various equipment designs, operating conditions, and fluid types.

c. Longevity and Reliability: Properly installed and maintained mechanical seals can have a long service life, providing reliable performance even in demanding operating environments.

d. Reduced Friction and Heat Generation: Mechanical seals are designed to minimize friction and heat generation, resulting in improved equipment efficiency and reduced energy consumption.

Oil Seals:

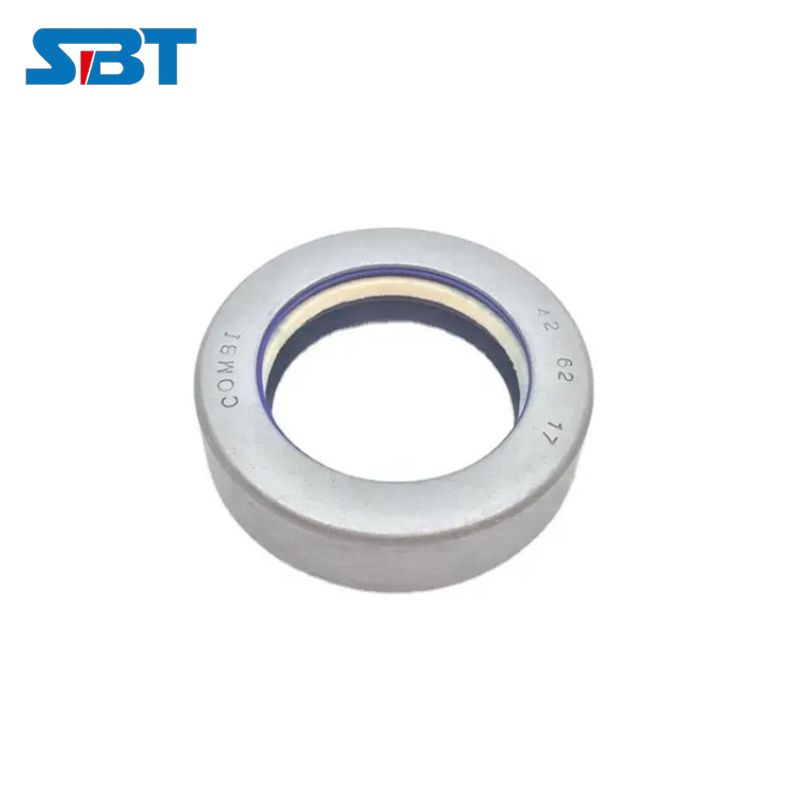

Design and Function: Oil seals, also known as rotary shaft seals or radial shaft seals, are simple sealing devices designed to prevent the leakage of lubricants, such as oil or grease, along rotating shafts. They typically consist of a flexible sealing lip, a metal case, and a spring. Oil seals create a barrier between the rotating shaft and the stationary housing, retaining lubricants and excluding contaminants from entering the system.

Application: Oil seals are commonly used in applications involving rotating shafts, such as motors, engines, gearboxes, and axles. They are primarily utilized to seal the lubricants within the system and protect the rotating shafts from external contaminants, ensuring proper lubrication and preventing premature wear or damage. Oil seals find application in industries such as automotive, manufacturing, agriculture, and construction.

Performance and Advantages: Oil seals offer several advantages, including:

a. Lubricant Retention: Oil seals effectively retain lubricants within the system, preventing leakage and ensuring proper lubrication of rotating components.

b. Contamination Exclusion: Oil seals create a barrier against external contaminants, such as dust, dirt, or moisture, preventing their entry into the system and protecting the rotating components from potential damage.

c. Ease of Installation: Oil seals are relatively easy to install and replace, requiring basic tools and minimal expertise.

d. Cost-Effective: Compared to mechanical seals, oil seals are generally more cost-effective, making them a popular choice for applications where moderate sealing performance is sufficient.

Conclusion:

Mechanical seals and oil seals serve distinct sealing purposes in different applications. Mechanical seals are complex devices used in rotating equipment to prevent fluid leakage, particularly in demanding and high-performance applications. On the other hand, oil seals are simpler sealing devices primarily employed in rotating shafts to retain lubricants and exclude contaminants. Understanding the differences between mechanical seals and oil seals will help you select the most appropriate sealing solution for your specific application, ensuring optimal performance, longevity, and reliability of your mechanical systems.