How Does an Adjustable Threading Die Work? Exploring Precision in Thread Cutting

An adjustable threading die is a versatile and indispensable tool used in metalworking and machining processes to create threads on cylindrical workpieces such as rods, bolts, and pipes. This precision tool offers an efficient and accurate method of producing threads, allowing for customization and adaptability to various threading needs. In this article, we delve into the inner workings of an adjustable threading die, its components, and the process of thread cutting it facilitates.

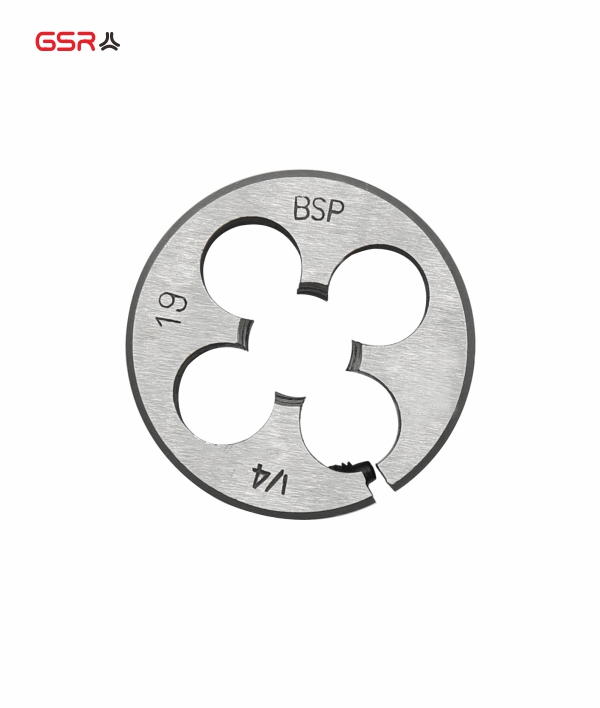

The Anatomy of an Adjustable Threading Die: Components and Design

An adjustable threading die consists of several essential components that work in harmony to produce uniform and accurate threads. The primary components include:

Die Body: The main body of the die holds the threading inserts or blades in place and provides structural support.

Threading Inserts (Blades): These are the cutting tools that physically remove material to form the threads. Threading inserts are typically made from high-speed steel (HSS), carbide, or other durable materials capable of withstanding the cutting forces and heat generated during the process.

Adjustment Mechanism: The heart of the adjustable threading die is its adjustment mechanism, which allows users to modify the size of the threads being cut. This mechanism typically involves movable parts that control the distance between the threading inserts, enabling the creation of threads with different pitch and diameter.

Locking Mechanism: To ensure precision and consistency, an adjustable threading die includes a locking mechanism that secures the adjustment in place during the cutting process.

The Thread Cutting Process: Step by Step

The process of using an adjustable threading die to cut threads involves several intricate steps, each contributing to the overall precision and quality of the finished threads:

Workpiece Preparation: The workpiece, usually a cylindrical rod or pipe, is prepared by ensuring it is clean and properly secured in a lathe or threading machine.

Die Installation: The adjustable threading die is carefully selected based on the desired thread specifications. It is then installed onto the threading machine or lathe, ensuring proper alignment and secure attachment.

Die Adjustment: One of the key advantages of an adjustable threading die is its ability to cut threads of various sizes. The operator adjusts the die's threading inserts using the adjustment mechanism, setting the desired pitch and diameter.

Initial Pass: The die is brought into contact with the workpiece, and the initial pass is made. During this step, the threading inserts make initial contact with the workpiece, creating a guide for subsequent passes.

Progressive Passes: Depending on the thread depth and quality required, multiple progressive passes are made. In each pass, the adjustable threading die cuts deeper into the workpiece, gradually forming the complete thread profile.

Constant Lubrication: Throughout the thread cutting process, lubrication is applied to reduce friction and dissipate heat. This ensures smoother cutting and prolongs the life of the threading inserts.

Finishing Pass: Once the desired thread depth is achieved, a final pass is made to ensure uniformity and precision. This pass may involve finer adjustments to enhance thread quality.

Thread Inspection: After the cutting process, the newly formed threads are carefully inspected using thread gauges or micrometers to ensure they meet the specified dimensions and tolerances.

Advantages of Using Adjustable Threading Dies

The utilization of adjustable threading dies offers several distinct advantages in metalworking and machining:

Versatility: Adjustable threading dies can produce threads of varying sizes and pitches, offering versatility in thread creation.

Cost-Efficiency: One adjustable threading die can be used to cut threads of different specifications, reducing the need for multiple dies.

Customization: Operators can easily adjust the die to create custom threads to suit specific project requirements.

Time Savings: The efficient and precise cutting process of adjustable threading dies reduces production time and increases throughput.

Ease of Use: With proper training, operators can quickly learn to use adjustable threading dies effectively, contributing to enhanced productivity.

In conclusion, the functionality of an adjustable threading die is a testament to the intricacies of modern machining and metalworking. By combining precision engineering with user-friendly design, this tool empowers manufacturers and machinists to create threads of exceptional quality and consistency. Whether in industrial settings or small workshops, the adjustable threading die remains an essential companion in the journey of turning raw materials into finely threaded masterpieces.