How are stainless steel plates manufactured?

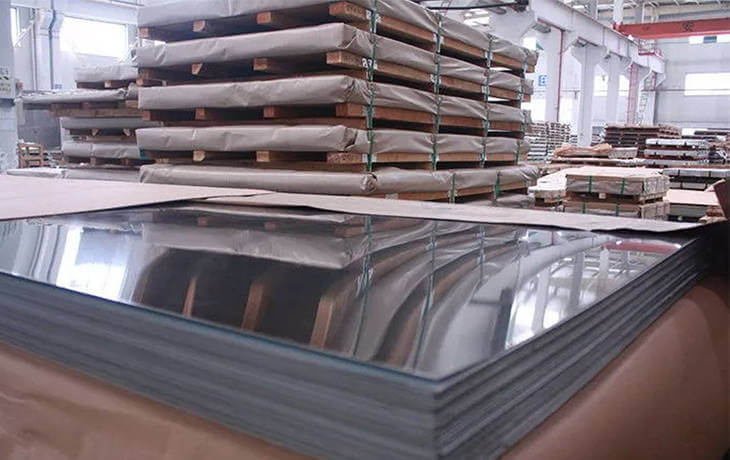

Stainless steel plates are versatile and widely used in various industries, including construction, automotive, manufacturing, and food processing. Understanding the manufacturing process of stainless steel plates provides valuable insights into their quality, properties, and applications.

1. Raw Materials and Melting:

To begin the manufacturing process, high-quality raw materials such as iron ore, chromium, nickel, and other alloying elements are carefully selected. These materials undergo a melting process in electric arc furnaces or induction furnaces, where they are heated to extremely high temperatures until they liquefy.

2. Casting and Solidification:

Once the raw materials are melted, the liquid steel is poured into large molds to form slabs. The molds are designed to create the desired dimensions and thickness of the stainless steel plates. During the solidification process, the steel cools and transforms into a solid state.

3. Hot Rolling:

After solidification, the slabs undergo hot rolling, which involves passing them through a series of high-pressure rollers. This process reduces the thickness and refines the structure of the steel, resulting in plates with uniform thickness and improved mechanical properties. The hot rolling process also enhances the surface finish of the plates.

What Are OCTG Tubes?

What Are Carbide End Mills Used for?

Endless Round Slings vs. Chain Slings: Comparing Strength, Durability, and Flexibility

What Are the Common Uses of Domed Nuts?

Choosing the Right Rubber Slurry Pump: A Comprehensive Buyer's Guide

what's a throwout bearing

What are the Problems with Gate Valve 20k?

4. Annealing and Pickling:

Following hot rolling, the stainless steel plates go through an annealing process to relieve internal stresses and improve their machinability. Annealing involves heating the plates to a specific temperature and then slowly cooling them. Subsequently, the plates undergo pickling, where they are immersed in an acid solution to remove surface impurities and scale.

5. Cold Rolling and Leveling:

After pickling, the plates are cold-rolled to further reduce their thickness and enhance their dimensional accuracy. Cold rolling involves passing the plates through a series of rollers at room temperature. This process imparts a smooth, uniform surface finish and tight thickness tolerances to the plates. Following cold rolling, leveling is performed to ensure the plates are flat and free from any distortions.

6. Finishing Processes:

To achieve specific surface finishes and enhance the aesthetic appeal of the stainless steel plates, various finishing processes are employed. These include grinding, polishing, and brushing. Grinding removes any surface imperfections, while polishing and brushing create a reflective or textured surface, depending on the desired finish.

7. Quality Control and Inspection:

Throughout the manufacturing process, stringent quality control measures are implemented to ensure that the stainless steel plates meet the required standards. The plates undergo thorough inspections, including dimensional checks, visual examinations, and tests for mechanical properties, such as tensile strength and hardness. Only plates that pass these quality checks are deemed suitable for further use.

The manufacturing process of stainless steel plates involves a series of carefully orchestrated steps, from selecting high-quality raw materials to implementing quality control measures. Each stage plays a crucial role in determining the final properties and characteristics of the plates. By understanding this manufacturing process, engineers, designers, and end-users can make informed decisions regarding the selection and utilization of stainless steel plates in their respective applications.

Additional reading:Unlocking the Flow: Mastering the Dynamics of Butterfly Valves

Are Chinese bearings any good?

10 Best Tips for Buying Embossed Stainless Steel Plates?

Mastering Water Ripple Stainless Steel Panel Installation

How long does galvanized steel last outside?

Which design trends will elevate gold stainless steel sheet?

Revolutionizing Urban Safety: Anti Climb Fencing?