Harness the Potential of Multi Head Weighers

In today's fast-paced business landscape, optimizing efficiency and accuracy in production processes is paramount for any company seeking to stay competitive. One area where this is particularly crucial is in the field of weighing and packaging. As technology continues to advance, businesses are constantly on the lookout for innovative solutions that can streamline their operations and deliver consistent results. Multi-head weighers have emerged as a game-changing tool, revolutionizing the way products are weighed and packaged. In this article, we will explore the potential of multi-head weighers and how they can help businesses outperform their competitors.

What Are Multi-Head Weighers?

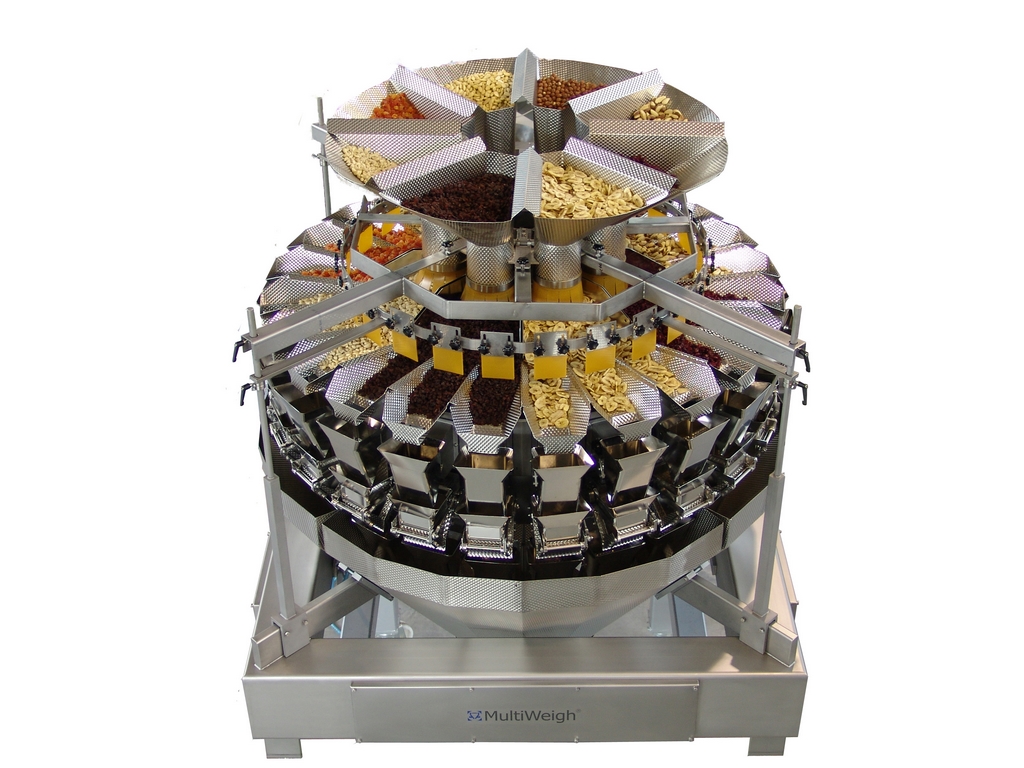

Multi-head weighers, also known as combination weighers, are sophisticated weighing systems used in various industries, including food processing, pharmaceuticals, and manufacturing. These machines employ advanced technology to accurately measure and distribute products into packaging containers. They are equipped with multiple weighing heads, typically ranging from 10 to 24, which work in tandem to achieve high-speed and precise weighing operations.

Unleashing Efficiency and Speed

One of the primary advantages of multi-head weighers is their ability to significantly enhance efficiency and speed in the weighing and packaging process. These machines employ a combination of advanced algorithms, load cells, and sensors to swiftly calculate the optimal weight for each product. By simultaneously weighing multiple items, they can drastically reduce production time, ensuring that goods are packaged promptly and delivered to customers in a timely manner.

Enhanced Accuracy and Consistency

Accuracy is paramount when it comes to weighing and packaging products. Multi-head weighers excel in this aspect, offering unparalleled precision and consistency. Through the use of advanced digital technology, they minimize weighing errors, virtually eliminating variations in product weight. This level of accuracy not only ensures customer satisfaction but also reduces waste and improves overall product quality.

Versatility Across Industries

Multi-head weighers have found widespread applications across various industries due to their adaptability and versatility. Whether you are packaging snack foods, fresh produce, frozen goods, or even non-food items, multi-head weighers can be tailored to suit your specific requirements. With adjustable settings and customizable parameters, these machines can handle a wide range of products, making them an indispensable asset for businesses with diverse product portfolios.

Additional reading:What is a Vertical Facing and Centering Machine, and how does it function?

How To Maintain Scissor Lifts And Boom Lifts?

Exploring Different Maize Flour Milling Machine Types and Their Applications

Industrial Giants: Where Four-Row Cylindrical Roller Bearings Shine

Understanding the Process of EPS Shape Molding

Optimizing Air Quality: The Benefits of Custom Industrial Fans

What does a CNC lathe produce?

User-Friendly Interface and Integration

While the technology behind multi-head weighers is highly advanced, their user interfaces are designed to be intuitive and user-friendly. This ensures that operators can quickly grasp the machine's functionalities, minimizing training time and maximizing productivity. Furthermore, these weighers can seamlessly integrate with existing production lines, allowing for smooth coordination and minimal disruption to ongoing operations.

Reduced Labor Costs and Increased ROI

Investing in multi-head weighers can yield substantial long-term benefits for businesses. By automating the weighing and packaging process, companies can significantly reduce labor costs and allocate resources more efficiently. Moreover, the increased efficiency and accuracy of multi-head weighers result in higher output and improved product quality, ultimately translating into increased customer satisfaction and higher return on investment (ROI).

Maintaining Hygiene and Safety Standards

In industries such as food processing and pharmaceuticals, maintaining stringent hygiene and safety standards is of paramount importance. Multi-head weighers are designed with this in mind, incorporating features that facilitate easy cleaning and ensure compliance with industry regulations. Stainless steel construction, removable contact parts, and sanitary design elements enable thorough sanitation, minimizing the risk of contamination and safeguarding product integrity.

Optimizing Production Flexibility

Flexibility in production is essential for businesses to adapt to changing market demands and introduce new products quickly. Multi-head weighers provide the necessary flexibility by allowing seamless product changeovers and adjustments in packaging configurations. With minimal downtime and efficient changeover procedures, companies can optimize their production processes and meet the evolving needs of their customers.

Conclusion

In the ever-evolving landscape of modern business, harnessing the potential of multi-head weighers is key to gaining a competitive edge. These advanced weighing systems offer unparalleled efficiency, accuracy, and versatility, enabling businesses to streamline their operations and deliver high-quality products consistently. By investing in multi-head weighers, companies can unlock new levels of productivity, reduce costs, and enhance customer satisfaction. Embrace the power of multi-head weighers, and propel your business towards success.

Additional reading:Unleashing the Underground: A Comprehensive Guide to DTH Hammers

Tube Making Machine: Revolutionizing Manufacturing

What Are The Characteristics of Automatic Plastic Glove Machine?

How to Choose the Right Concrete Batching Plant for My Construction Project?

Hollow Core Slab Machine: A Game Changer in Construction?

Are Fiber Laser Cutting Machines the Future of Precision Manufacturing?

What Robotic Soldering Can Do to Your Electronics Manufacturing Line