Customized Investment Casting vs Traditional Casting Methods: What's Best?

When it comes to producing high-quality metal parts, casting methods play a crucial role in achieving the desired results. Two popular casting techniques used in the industry are traditional casting methods and customized investment castingcustomized investment casting. But which method is the best choice for your specific project needs? Let's dive into the details and find out!

What is Traditional Casting?

Traditional casting, also known as sand casting, is one of the oldest and most widely used casting methods in the industry. In this process, a mold is created using a mixture of sand and a binder material, which is then filled with molten metal to create the desired shape. Once the metal cools and solidifies, the mold is removed, leaving behind the final part.

What is Customized Investment Casting?

Customized investment casting, on the other hand, is a more intricate and specialized casting method. In this process, a wax pattern of the part is created and coated with a ceramic shell. The wax is melted out, leaving behind a hollow ceramic mold that is then filled with molten metal. Once the metal cools and solidifies, the ceramic shell is broken away to reveal the final part.

Comparison of the Two Methods:

1. Surface Finish:

Traditional casting methods typically result in rougher surface finishes compared to customized investment casting. The precision and intricacy of the ceramic molds used in investment casting allow for smoother and more detailed parts.

2. Tolerance and Accuracy:

Customized investment casting offers higher dimensional accuracy and tighter tolerances compared to traditional casting. This makes it a preferred choice for projects that require precise and intricate parts.

Additional reading:What to Expect from a Die Cast Pump Housing Exporter?

4 Tips to Select the Right Reducer Box Exporter

What are the standards for fasteners?

Maximize Profit: The Secrets of Stainless Steel Casting Bulk

How to Choose the Best Meat Grinder Body Export?

Smithey Cast-Iron Skillet Review: Are They Worth the Price?

4 Tips to Select the Right Steel Alloy Casting Exporter

3. Cost:

Traditional casting methods are generally more cost-effective for larger production runs due to lower tooling and setup costs. On the other hand, customized investment casting is ideal for smaller production runs or specialized parts that require high precision.

4. Complexity:

Customized investment casting is better suited for complex and intricate parts, thanks to its ability to create detailed molds with precise dimensions. Traditional casting methods may struggle with intricate shapes and details.

So, Which Method is Best for Your Project?

Ultimately, the choice between customized investment casting and traditional casting methods will depend on your specific project requirements. If you need high precision, intricate details, and superior surface finishes, customized investment casting may be the best option for you. However, if cost-effectiveness and simplicity are your priorities, traditional casting methods might be the way to go.

In conclusion, both casting methods have their own set of advantages and limitations. It's essential to assess your project needs and consult with a reputable supplier to determine the best casting method for your specific requirements. Whether you choose traditional casting or customized investment casting, it's crucial to work with a reliable supplier who can deliver high-quality parts that meet your expectations.

If you're unsure about which casting method is right for your project, feel free to contact us for expert guidance and assistance. Our team of experienced professionals can help you choose the best casting method to achieve optimal results for your project.

Contact us to discuss your requirements of china high quality stainless steel pipe fitting handle, y strainer direction. Our experienced sales team can help you identify the options that best suit your needs.

Additional reading:4 Tips to Select the Best Stainless Steel Supplier for Your Project

How to Optimize Aluminum Casting Bulk Production?

Essential Guide to Aluminum Casting: Techniques & Benefits

How To Determine Your Forklift Capacity When Adding ...

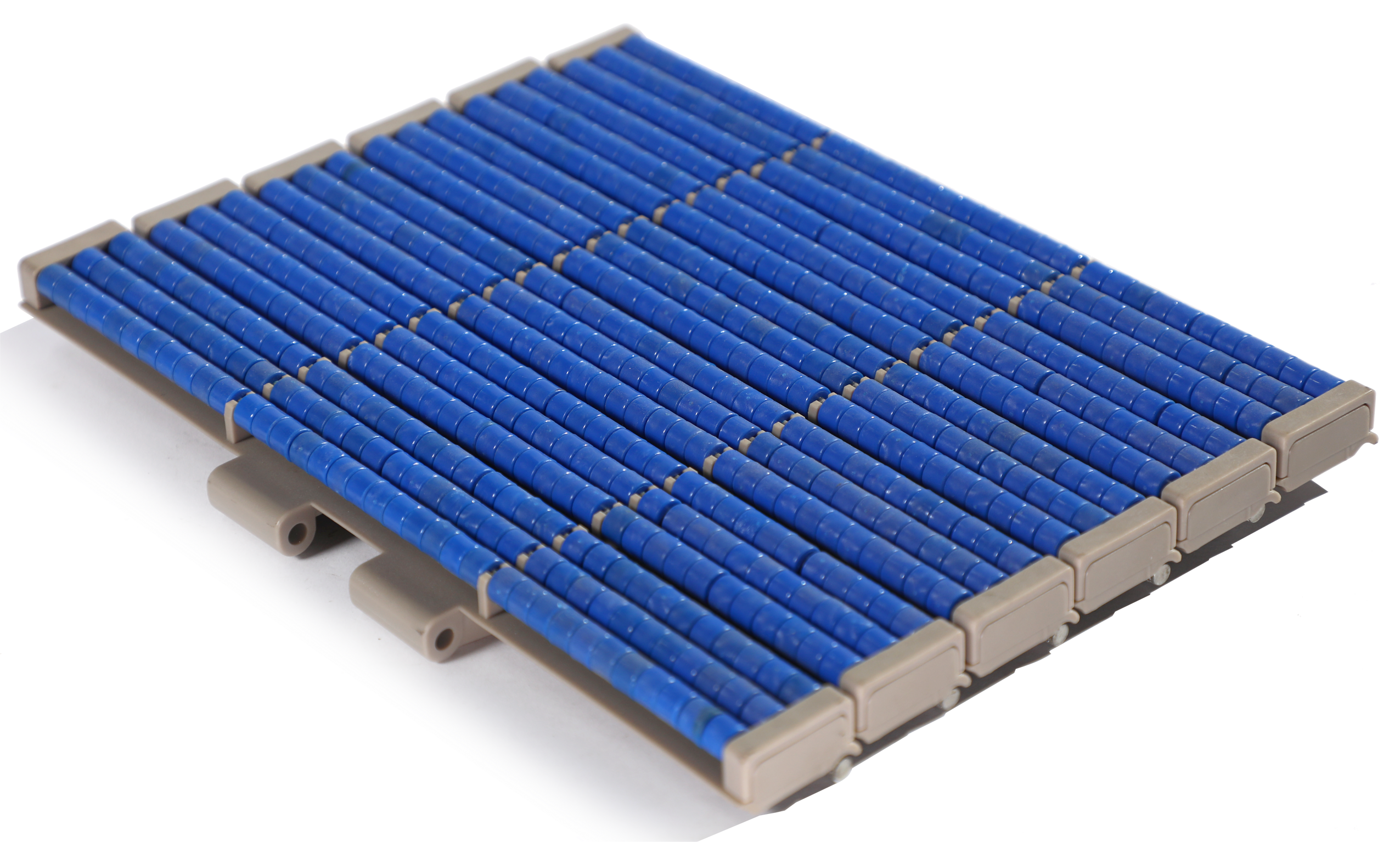

How Should We Innovate Tape Feeders Today?

Key Questions to Ask When Choosing 00141294 Tape Feeder 32mm X with Sensor

The Advantages of Partnering with a Casting Pump Body Supplier