What is the best way to store and maintain beer equipment to ensure longevity and quality?

Proper storage and maintenance of beer equipment are vital for ensuring the longevity and quality of your brewing endeavors. By implementing effective practices, you can protect your investment, prevent contamination, and optimize the performance of your equipment. In this comprehensive guide, we will explore the best ways to store and maintain beer equipment, providing you with valuable tips and insights to help you achieve optimal results.

Choosing an Ideal Storage Space

To ensure the longevity and quality of your beer equipment, selecting an appropriate storage space is crucial. Consider the following factors:

1.1 Temperature Control

Maintain a consistent and moderate temperature in the storage area to prevent damage and maintain the integrity of the equipment. Avoid extreme temperatures, as they can affect the materials and functionality of the equipment.

1.2 Protection from Light

Shield beer equipment from direct sunlight or excessive artificial light to avoid UV degradation. Store equipment in a dark or dimly lit area or use opaque covers to prevent light exposure.

Cleaning and Sanitizing

Regular cleaning and sanitizing are essential to maintain hygiene and prevent the buildup of contaminants. Follow these guidelines:

2.1 Proper Cleaning Procedures

Thoroughly clean all equipment after each use to remove residue, yeast, and other impurities. Use appropriate cleaning agents and brushes suitable for each specific component. Follow the manufacturer's instructions for optimal cleaning practices.

2.2 Effective Sanitization Methods

Sanitize all equipment surfaces using brewery-approved sanitizing solutions. Ensure proper contact time and follow recommended dilution ratios. Pay particular attention to areas that come into direct contact with beer, such as fermenters, hoses, and valves.

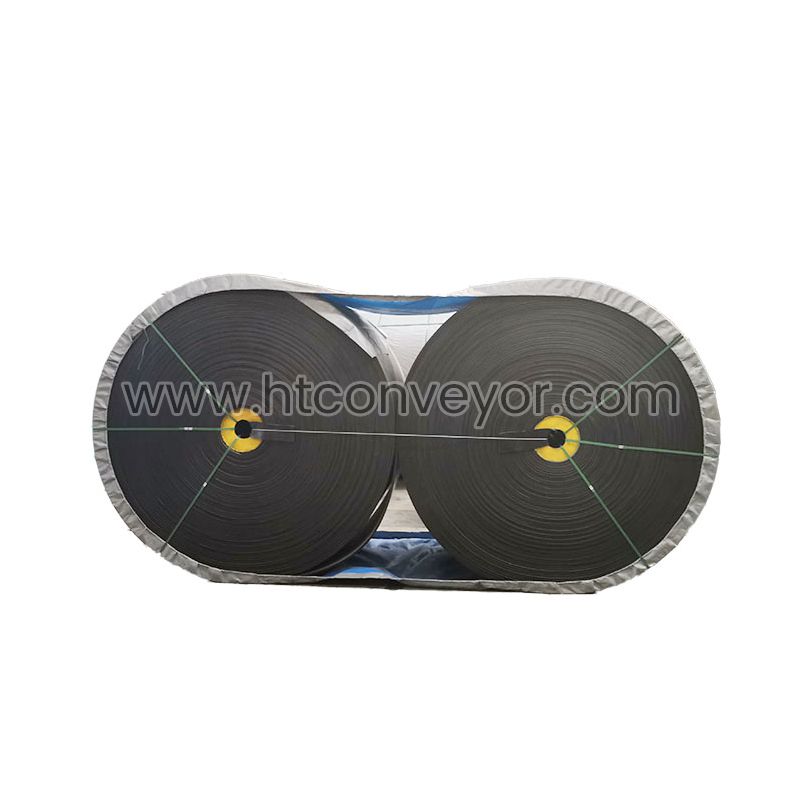

Conveyor Belt: Streamlining Material Handling with Efficiency and Precision

A Comprehensive Guide to Brew House Setup and Operation

What Are the Types of Excavators?

The Laser Cutter Revolution: Transforming Design and Manufacturing

The Development Direction of Heat Treatment

How Does a Plastic Injection Molding Machine Work?

What Are Some Fun Facts About Drilling Rigs?

Equipment Maintenance

Regular maintenance is key to extending the lifespan and maximizing the performance of your beer equipment. Consider the following maintenance practices:

3.1 Inspection and Repair

Periodically inspect all equipment for signs of wear, damage, or leaks. Check seals, gaskets, and connections for tightness and functionality. Address any issues promptly to prevent further damage and maintain optimal brewing conditions.

3.2 Lubrication

Apply food-grade lubricants to moving parts, such as pumps and valves, to ensure smooth operation. Follow the manufacturer's recommendations for lubrication intervals and use appropriate lubricants.

Organization and Inventory Management

Efficient organization and inventory management help streamline your brewing process and prevent equipment-related issues. Consider these practices:

4.1 Equipment Tracking

Implement a system to track and document the usage, cleaning, and maintenance of your beer equipment. This helps identify patterns, schedule routine maintenance tasks, and ensure timely replacements or upgrades.

4.2 Proper Storage for Small Items

Store smaller equipment components, such as fittings and airlocks, in designated containers or bins. Label and categorize these items for easy access and to minimize the risk of misplacement or loss.

Conclusion:

By following the best practices outlined in this guide, you can effectively store and maintain your beer equipment, ensuring its longevity and preserving the quality of your brews. Remember to choose an ideal storage space, prioritize cleaning and sanitizing, perform regular equipment maintenance, and maintain an organized inventory system. With these strategies in place, you'll be able to enjoy the optimal performance and longevity of your beer equipment, leading to exceptional brewing experiences.

Additional reading:Operation Steps of Vertical Pressure Steam Sterilizer

How Does The Rising Film Evaporator Work?

Pallet Stretch Wrapping Machine: Ensuring Efficient and Secure Palletization

Unlocking Precision and Efficiency with Large Format Laser Cutting Machines

What are the types of gear machines?

What Are The Benefits of Using Induction Pipe Bending Machine?

Considerations When Choosing a Chocolate Coating Machine